The California Mechanical Code (CMC) is one of thirteen parts of the California Building Standards Code that is adopted into law every three years by the California Legislature. The other 49 U.S. states adopt similar safety codes, which generally include the following titles (preceded by

One of the primary objectives of the mechanical code is to help ensure that heating, ventilating, and air conditioning equipment installed in buildings are designed, operated, and maintained safely. Many HVAC systems utilize natural gas, which is highly flammable and can cause explosions.

This author investigated a natural gas explosion (also called deflagration, or subsonic combustion wave) that was caused by a series of maintenance errors, a heater malfunction, and a major code violation.

The maintenance errors caused natural gas to be released into a heater room, the code violation permitted the natural gas to accumulate in the room instead of being safely vented outdoors, and the malfunction permitted the heater to re-start automatically in an unsafe state, which ignited the explosion. Two workers received serious burn injuries from the incident, but the explosion wasn’t strong enough to damage the building.

It was difficult to rank the errors and defects according to their level of egregiousness, but the worst one was undoubtedly the combined design defect and construction defect associated with the building that housed the gas-fired heater. The heater was located at ground level inside a 23-foot tall enclosure construction from concrete masonry units (i.e., cinder blocks). The architect was responsible for the defective design, which contemplated heating equipment inside the room but didn’t incorporate the code-required ventilation area. The general contractor and appliance installer were responsible for allowing the heating equipment to be installed in the room without the proper ventilation.

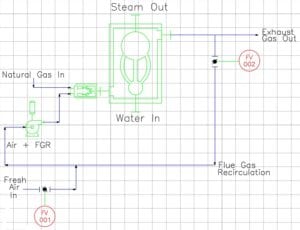

The CMC requires ventilation at the top of any enclosure that houses gas-fueled appliances. The purpose is to vent natural gas (which is lighter than air) in the event of a substantial release of gas into the indoor space. Allowing flammable gas to accumulate in an enclosure is the first step in the process of forming an explosive device that lacks only an ignition source to turn into a horrific fireball or a destructive blast wave. The subject room was well sealed along the upper 75% of its height but was equipped with a louvered door at the bottom that effectively allowed combustion air into the room to supply oxygen for the heating appliance. Combustion products from the heater were vented directly to the outdoors by an electric blower, and the replacement air entered through the door louvers.

When the gas pipe developed a leak (the facts weren’t entirely clear about the size of the leak was or how it began), the gas rose to the ceiling and accumulated there, displacing the air below it to the outside environment through the door louvers.

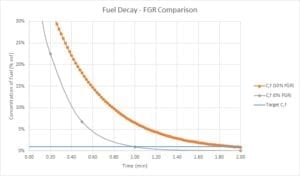

This author performed a Large Eddy Simulation (LES) of the gas accumulation phase which showed the steady-state fuel gas concentration in the upper three-quarters of the room to be substantially greater than the Upper Flammable Limit for natural gas (approximately 15 percent by volume). This fact turned out to be the sole reason the building didn’t explode – a large fraction of the fuel gas present in the room had accumulated in zones that were too rich to burn (not enough oxygen present).

Nevertheless, when the employees were instructed to enter the room and shut off the gas to the heater, their motion created a flammable zone in some portion of the lower 25% of the room’s volume. When the defective heater ignited the flammable mixture as they were exiting the room, the fireball that was created pushed flames out through the open door and burned them badly as they tried to escape. Thankfully both survived.

Posted below are two videos showing the LES simulations for Case 1 – as installed without any venting at the ceiling, and Case 2 – as required by code, with a code-compliant opening of only 150 square inches of flow area at the top of the heater room. Case 1 shows high gas concentration (red) from ceiling down to the top louver of the entry door when gas is flowing and no significant dissipation after the gas source is shut off. Case 2 shows a temporary accumulation of moderate gas concentration (green) until the gas source is shut off, after which full dissipation occurs through the upper vent. The simulation runs approximately 24x faster than real time.

This gas accumulation simulation (along with testing of the defective heater, timeline analysis of witness testimony, and plumber standard of care analyses) helped the parties reach a resolution in this case.